PCBA tools

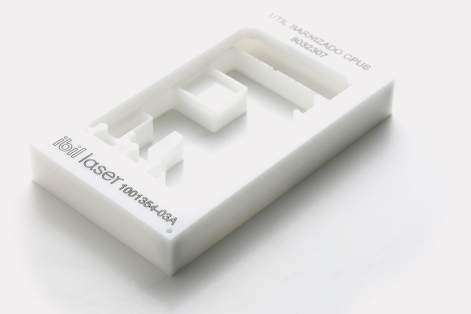

We design and manufacture precision PCBA tools.

Due to the EMS industry’s different needs, we offer custom-built solutions.

PCBA tools

From our process engineering department, working closely with our customer, we offer design, manufacturing and mounting of any type of tool, from the stencil printing process to depanelling, including any type of soldering.

We consider each project to be unique, so the tools designed and manufactured by Ibil Laser are said to be “custom-made”.

Types of PCBA tools

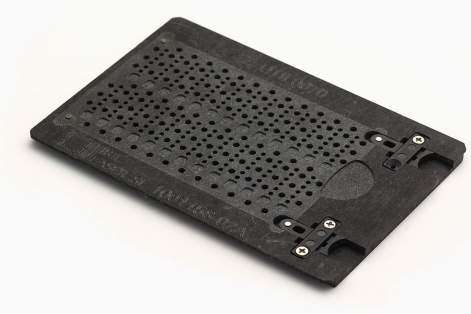

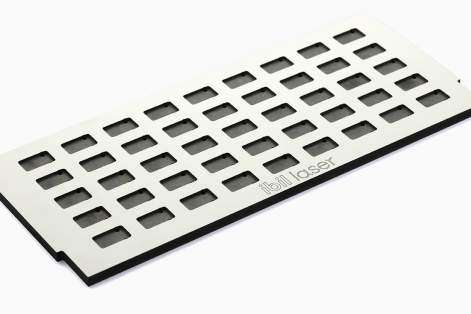

SMD supports are the perfect solution to make different types of PCB rigid: flexible, rigid-flexible or smaller thicknesses.

Stencil printing supports optimise the PCB support during the printing process.

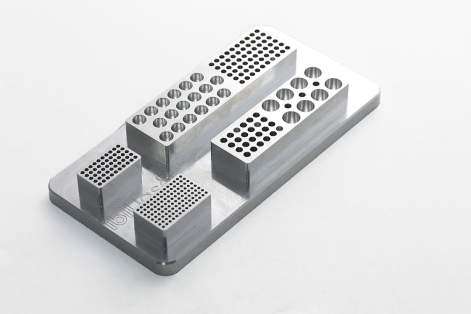

Jedec trays are a good complement to P&P for loose components, or any that do not come on reels.

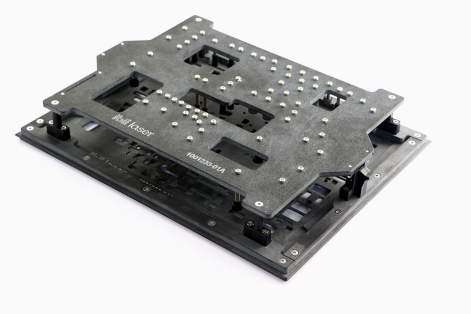

Adaptable solutions both for wave and selective soldering.

The tools, carriers or trays for wave soldering are used for soldering conventional or THT components.

The appearance of selective soldering technology heralded the need for less tooling in the THT soldering process, but this could not have been further from the truth.

Although soldering processes are usually automated, there are phases or processes where part or all of the soldering must be done by hand.

This type of tooling is used to pressure-assemble components, that may or may not be soldered subsequently.

Electronics are subject to high insulation requirements in some sectors, so different coating processes are applied to the PCBAs.

Usually, the assembly process is done at panel level, to optimise manufacturing times and costs.