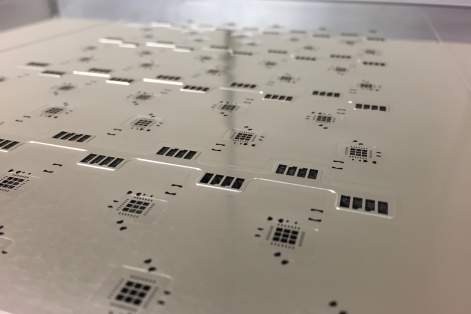

SMD Stencils

WE MANUFACTURE TOP QUALITY STENCILS.

We treat each project individually to optimize each printing result. “We bring all our experience and technology to the table.”

The stencil-printing process is make or break, affecting SMT assembly quality by 75-80%.

So, Ibil Laser can put a qualified team on the job, with vast experience, and specific latest-generation software and machinery to get the very best quality in all the SMD screen printing stencils that we manufacture.

Our team can recommend the best options for design, materials and additional processes for each project.

SMD stencils

We have a wide variety of stencil formats, using top quality materials. e.g. PHD or Fine Grain stainless steel, Nickel...and gauges to optimise your process results.

The Vector Guard system makes it possible to use different stencils within the same tensioning frame.

User-friendly rigid frame stencils require minimum set-up time.

Vector Guard High Tension stencils are designed for very demanding fine grain solder paste applications.

Self-tensioning foil stencils are the best option to optimise storage space.

Technologies and processes

We offer a wide range of additional technologies and processes to maximise the transfer and volume of solder paste deposited. e.g. Electropolishing, Nanocoating and Multilevel, using both microsoldering and micromachining technology.

EP-Gel electropolishing for SMD stencils reduces roughness around openings by improving how the paste is deposited on the PCB

Treating SMD stencils with a nanocoating improves the paste depositing process and requires fewer cleaning cycles.

Multilevel stencils using microsoldering offer greater control of the stencil printing process by using several thicknesses in the same stencil.

The multi-level micro-machining technology facilitates additional flexibility in both thicknesses and complex geometries.